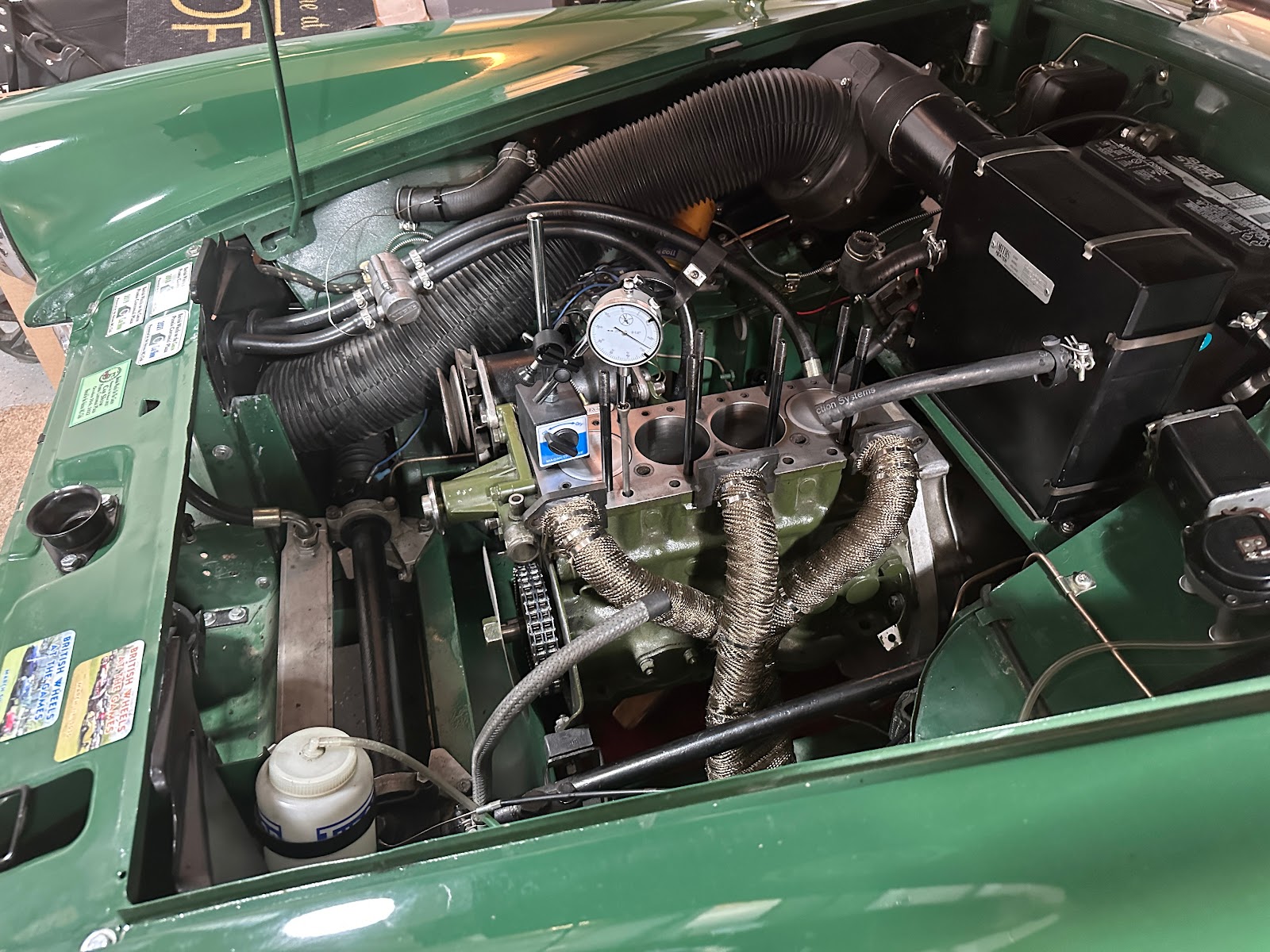

I had a good reason to clean up the engine bay. (Oil everywhere will do that.) It was easiest to remove the generator to get to the bits that were underneath. I figured, "Well, it's out... let's take a look."

Lucas C39/C40 dynamos (generators to us Yanks) are pretty simple devices. I've rebuilt this one already, and it was working fine... aside from slightly low voltage output at idle. It was also making a bit of noise at the rear bushing, which I figured was probably on its way out. I had not replaced it.

Here's the complete teardown of the dynamo. Teardown isn't difficult. The hardest part is using a small puller to separate the armature from the front plate's bearing.

I could see something I didn't like. The armature rear spindle is really scored. It wasn't this bad a few years ago, but there was wear.

A little research on the Googles shows these are readily available. Since C39/40 dynamos were used in everything in the 50s and 60s, even farm tractors (!), I found a replacement armature at a tractor supply store for $75, and brushes for $12.

The new armature is a nearly perfect fit dimensionally, being just a tad longer at the rear spindle.

I also ordered a new rear bushing.

Replacing the rear bushing isn't difficult, but takes a bit of care. Knocking the old one out was as easy as getting a thin screwdriver between the bushing and the housing, and then pulling it out with a needle nosed plier. (It was a LITTLE harder than that, but the bushing is copper and will bend/split with some persuasion.)

The bushing is actually three elements: a felt pad that holds oil, a retaining plate for the felt pad, and the bushing itself. The pad goes in first, followed by the plate (with the concave side toward the back), then the bushing. The retaining plate has little slots in it to let the oil ooze past it and onto the bushing.

Driving the new bushing in in was a bit of a chore. I sanded the outside of the bushing down a tad to get its outer diameter closer to the inner diameter of the hole, and then put the bushing in the freezer before tapping it into place.

Once in, I had to gently ream the bushing out a bit to gain enough clearance for the new armature to spin freely. I also slightly modified the rear spindle on the armature to make it a tiny bit shorter and gave it a taper to clear the retaining plate. This took some trial and error and a few test fittings to get right.

After all that, I filled the bushing with oil and let it soak down, repeating a couple of times over the course of a day so the bushing had a chance to soak up oil. I had soaked the bushing before as well.

Reassembly is straightforward. The armature goes back into the front plate, then is assembled to the main body, followed by installing the rear plate. There is a trick to installing the new brushes: Install the brushes, and push the retaining spring to the side of each. That holds the brushes apart so the rear plate can be installed to the armature and body. Then, flip the little springs to have them push on the back of the brush. This makes a real chore take about 30 seconds.

After some paint, she's done. Spinning by hand makes a couple of tenths of a volt, so I am pretty sure it's going to work.

I painted the generator body green as that is what it should be on a '65 (I had painted it black). I painted the pulley and fan black, even though they should be metal, just because I wanted to. I think it looks great.

Hopefully, that's a job done for another few decades. With regular oiling, it should last a long time.